嘉瑞药机

创新无国界,嘉瑞致健康

创新无国界,嘉瑞致健康

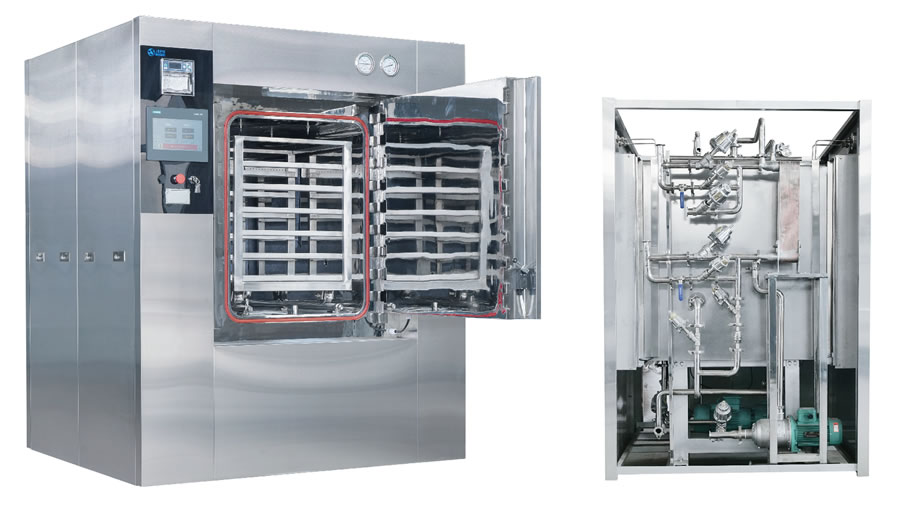

该系列水浴式灭菌柜利用过热循环水作为灭菌加热载体,对物品进行水淋式灭菌操作。在整个工作过程中,过热水运 行于一个相对封闭的循环系统。该设备具有温度均匀性好、温度调控范围宽(60-134℃)等一系列优点,并且有效防止工作 过程中的二次污染。该设备能广泛应用于制药行业对玻璃瓶装、安瓿瓶装、塑料瓶装、塑料软袋等液体进行高、低温灭菌 操作,同时也适合用于食品行业对各种密封包装、饮用液、罐头食品进行高低温灭菌操作。

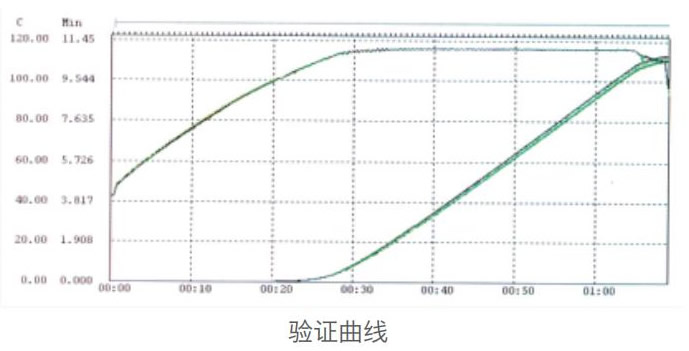

本机可选用计算机进行全过程监控。各种参数能进行修改,实时记录及打印输出,极大的提高了整机的可靠性和智能 化,使其能更好地适合于现代企业自动化生产的需要。

This series of water bath sterilization cabinet uses superheated circulating water as sterilization heating carrier to carry out water spray sterilization operation

on items. During the entire working process, the superheated water runs in a relatively closed circulation system. The equipment has a series of advantages such as good temperature uniformity, wide temperature control range (60-134℃), and effectively prevent secondary pollution in the working process. The equipment can be widely used in the pharmaceutical industry for high and low temperature sterilization of glass bottles, ampoules, plastic bottles, plastic soft bags and other liquids, but also suitable for the food industry for various sealed packaging, drinking liquid, canned food for high and low temperature steriliza- tion operation.

The machine can choose the computer to monitor the whole process. Various parameters can be modified, recorded and printed out in real time, greatly improving the reliability and intelligence of the whole machine, so that it can be better suited to the needs of modern enterprise automated production.

| 设计压力 Design Pressure |

0.3MPa | 蒸汽源压力 Steam Source Pressure |

0.4-0.6MPa |

| 设计温度 Design Temperature |

144 ℃ | 水源压力 Water Source Pressure |

0.1 -0.3MPa |

| 工作温度 Working Temperature |

60-134 ℃ | 压缩空气压力 Compressed Air Pressure |

0.5-0.7MPa |

| 热均匀度 Heat Equilibrium |

≤±1 ℃ | 纯水 Soft Water Pressure |

0.1-0.3MPa |

●主体内胆为优质304不锈钢,自动焊接一次成形。全不锈钢拉丝板装饰外罩。具有标准GMP验证接口,方便用户随时进 行设备验证。

●控制系统采用德国西门子PLC,触摸屏(可选配计算机控制),微型打印机系统。控制系统稳定,控制温度精确。并具有 完善的数据记录,打印,保存。

●管路系统采用美国ASCO气动阀和纳西姆真空泵等最优化配置。

●设备可选配自动进出柜系统,减轻工人的劳动强度。

● The chamber of the main body is high quality 304 stainless steel, which is automatically welded and formed once . All stainless steel wire-brushed panels trim the outer cover. With standard GMP authentication interface, it is convenient for users to verify equipment at any time.

● Control system using Germany Siemens PLC, touch screen (optional computer control), micro printer system. The control system is stable and the temperature is accurate. And it has perfect data recording, printing, saving functions.

● The piping system adopts the optimal configuration of ASCO pneu- matic valve and Nassim vacuum pump.

● The equipment can be optional automatic access cabinet system to

| 型号 Model |

内室尺寸 Chamber Size LxWxH(mm) |

外型尺寸 Overall Dimensions LxWxH(mm) |

蒸汽耗量 Steam Consumption (kg/cycle) |

水耗量 Water Consumption (kg/cycle) |

功率 Power(kw) |

重量 Weight(kg) |

| JR.SG-0.6 | 1050x680x850 | 1330x1650x1920 | 35 | 500 | 2.5 | 1200 |

| JR.SG-1.0 | 1250x750x1100 | 1530x1900x2000 | 45 | 600 | 4.5 | 1500 |

| JR.SG-1.2 | 1500x750x1100 | 1780x1900x2000 | 50 | 800 | 4.5 | 1700 |

| JR.SG-1.5 | 1820x750x1100 | 2100x1900x2000 | 60 | 1000 | 4.5 | 1900 |

| JR.SG-1.8 | 2200x750x1100 | 2480x1900x2000 | 65 | 1200 | 4.5 | 2100 |

| JR.SG-2.0 | 2450x750x1100 | 2730x1900x2000 | 70 | 1300 | 4.5 | 2300 |

| JR.SG-2.5 | 1700x1000x1500 | 2050x2200x2200 | 80 | 1500 | 5.5 | 2800 |

| JR.SG-3.0 | 2000x1000x1500 | 2350x2200x2200 | 100 | 1800 | 5.5 | 3200 |

| JR.SG-4.0 | 2700x1000x1500 | 3050x2200x2200 | 120 | 2200 | 6.5 | 3800 |

| JR.SG-5.0 | 3400x1000x1500 | 3750x2200x2200 | 150 | 2500 | 7.5 | 4500 |

| JR.SG-6.0 | 4000x1000x1500 | 4350x2200x2200 | 180 | 2800 | 7.5 | 5200 |